Use of the Building Information Model (BIM) in the building and installation sectors is becoming increasingly noticeable. One of its uses is for sharing relevant information among the various project partners during the building process, according to pre-determined standards. The result is a considerable acceleration of the building process and reduced failure costs. The current digiGO project plays an important part in stimulating digital collaboration between construction partners. The goal is to make the whole sector faster and smarter and to accelerate the digitalisation of the built environment.

Does this apply only to buildings or can we also maybe take it to apply to ships and/or offshore installations too? Jeroen Mackaij, BIM Manager at SPIE Building Solutions B.V., gives us his vision on this:

'“Built Environment" covers almost all constructions created by humans (or by a robot or CAD/CAM machine controlled (indirectly) by a human). That's why as far as I can see, the maritime objects mentioned are also constructions, just as bridges and tunnels or works of art are.'

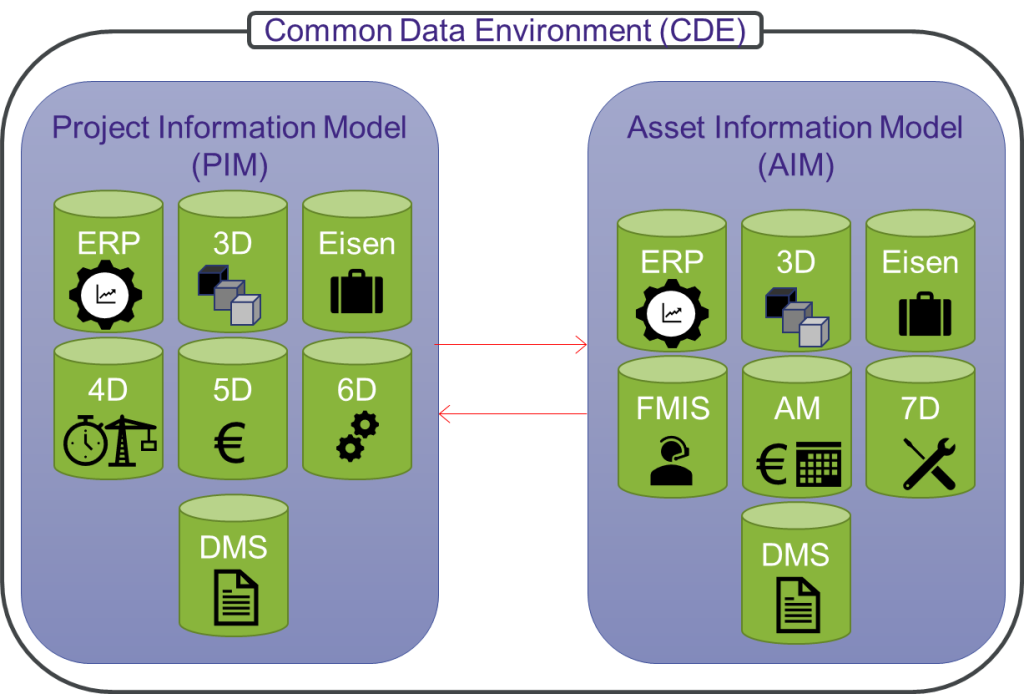

Not only that, but the use of BIM leads to the creation of a digital twin of the object realised. When that's connected to sensor data in real time, we're talking about a real digital twin with which simulations can be carried out. In the digital version, all the technical components of the object are specified accurately.

That offers the possibility of relying on the digital twin through the building phase and the entire lifecycle of the object for a number of purposes, such as implementing repairs correctly, replacing parts and planning and carrying out maintenance work.

Predictive maintenance is an essential part of modern maintenance strategies and uses data analyses to predict when a machine or other asset will need replacing, for example. This helps prevent disruptions, reduce downtime and enable maintenance to be carried out more efficiently after the right materials have been ordered well on time from the right supplier(s).

Use of the One Maritime Data Standard (OMDS) and the 2BA platform as a central 'counter' (with more than 28 million technical products and trade articles) are important preconditions both for using BIM and the digital twin and for a standardised approach to the maintenance throughout the entire lifecycle of the object built.

Would you like to know what prospects BIM and use of the 2BA data pool offer for your company and for the maritime sector as a whole? If so, don't hesitate to fill in the contact form.

We're happy to inform you about such matters. We will also show you how in future, you will have millions of technical products and corresponding trade information, classified according to ETIM, at your disposal!