Use of standardised data in the maritime sector is becoming increasingly important if efficiency and safety in the sector are to be improved. The One Maritime Data Standard (OMDS) is an initiative that aims to create a single common language for all maritime product data and related trade data, regardless of source or destination.

In an interview with OMDS, Maarten Mackaaij and André Hagenaar, both of whom work at ERIKS, share their vision on the importance of the OMDS for their company and the maritime sector as a whole.

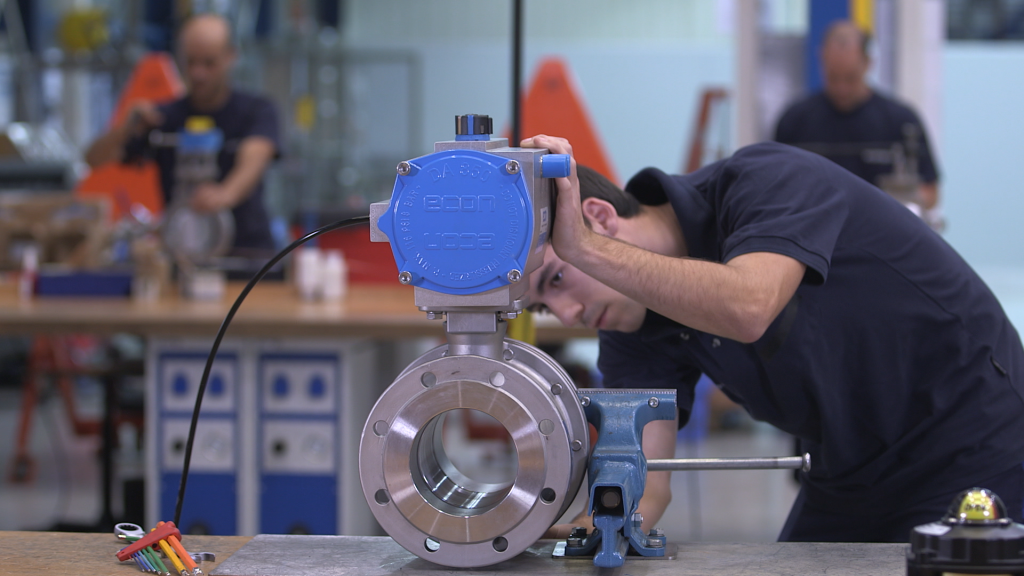

ERIKS is an experienced and specialised industrial service provider with a single mission: making companies better and more efficient through its technological knowledge and skills.

André Hagenaar has been working at ERIKS since 2005, currently as e-Business Specialist. His focus is on connecting business relations' ERP applications to the ERIKS system, for the automated processing of transactions.

He emphasises the importance of standardised and centralised data for the maritime industry and regards the One Maritime Data Standard (OMDS) as an important development for the sector.

Hagenaar: 'It saves so much coordination between all those business relations. It would be a huge advantage to the entire maritime sector if we were to introduce a single article standard and a single way of mutually exchanging data. How can we make sure we have one language and one point where we exchange master data in a structured way? I think that's what is really important.' Maarten Mackaaij, Head of Digital and Onsite sales at the same industrial service provider adds: 'ERIKS is a one-stop-shop for a variety of mechanical products and supplementary services and focuses on organising processes efficiently in order to keep costs low. We try our best to collaborate with our clients and look for ways to reduce costs. By organising processes efficiently, we realised years ago that we can add a great deal of value there and our department plays a major role in the difference in how various sectors organise their work.'

André Hagenaar has been involved in the OMDS initiative for some time already. 'I've been working on master data since 2010 and I've always been interested in the sector and utility. What I've been stressing to the maritime industry for years is: why do we all use different Excel files to exchange data? Let's cooperate on a single format, so that we don't have to keep carrying out the same, inefficient translation about which data is necessary.'

André: 'I think the most important aspect that needs to be tackled is 'where does the maritime sector differ from, for example, non-residential construction? And what challenges does that pose as far as the standard article exchange is concerned? One of the reasons could be that products don't always involve standard components. That's true of, for example, composite products and client-specific items.'

International competition is growing, in the maritime industry too. That means that in certain cases, the sector has to organise itself better or more efficiently. One of the things that a lot of time - and therefore a lot of money - is spent on is the purchasing and the design part, before subsequently getting the right batches in at the right moment. 'I think that if we, as a sector, want to maintain our competitive position, we will have to become more efficient in that too,' Maarten emphasises. 'And the OMDS and the facilitating 2BA data pool can be a huge help there.'

Maarten continues: 'Put simply, there are three things you can do with data: you can organise it yourself with your own code book, you can be totally dependent on the information you request from your suppliers or you can set up a central data pool, generic to the branch, from which you can extract the data and which as many suppliers as possible connect to and store their data centrally. In that case, as a supplier, you don't have to keep sending everything to a list of clients, but to just one data platform. And that's the 2BA data pool, the motor in the OMDS engine room.

The fact is that it's hopelessly dated, if people have to manually create new article numbers. It's not cost-efficient and it's prone to errors. Not only that, but you don't want to be constantly asking your suppliers: 'can you provide me with the data?'

ERIKS already has more than 461,000 trade records in the 2BA data pool, and around 862,000 product records, with more than 376,000 appendices. That's quite a number! As a multi-product specialist, the company naturally has multiple product lines. And in most of them, ERIKS can call itself expert or specialist. 'Of course, that also means you have to set yourself up as specialist, in terms of organisation too. For each product group, you have to think about how you want to organise and share information, and which.'

Maarten: 'There's so much to be won if you collaborate efficiently on this, as buyer and supplier. However, there are two processes: on the one hand, you have all the article data and on the other, the actual ordering process. And I think it makes sense to separate these two from each other, as it were, and put them in a matrix. You need the one product just now and then and with another, you know you'll have to order it often. If you compare them, you'll see clearly which way of ordering will turn out to be the most efficient.'

'You don't want to make a complicated matrix, but you can probably imagine that there are three ways of doing business in the maritime sector. First, you have a shipping company that has its own MRO needs, for example because something has broken that needs replacing quickly. Secondly, there are things you know you need once or twice a year. And thirdly, there are shipbuilders who produce in series, which makes it possible to plan clearly what is needed, when and in which quantities. Optimising catalogues can give better access to article data and lead to improvements in efficiency. Much could be won there.

Purchasing decisions are often made by the business but obviously, it isn't efficient to have to keep inventing the wheel.'

In the building and installation sectors, the Building Information Model (BIM) is being used more and more often to share relevant information among the various building partners, speeding up the building process and reducing failure costs.

In the end, the BIM results in a digital version of the object built, a digital twin that can be used throughout the object's entire life cycle for repairs, replacement of components or maintenance work, for example.

Use of the Uniform (3D) Objects Library (UOB) and the 2BA product data pool are essential parts of the BIM process, including support of the digital version of the object built. This makes it possible, even later, to order the right products or components from the right suppliers.

The strategy of the branch organisation NMT (Netherlands Maritime Technology) focuses on making the Dutch maritime manufacturing industry more efficient, faster, by means of digitalisation. By realising further integration and efficiency benefits with the help of the 2BA product data pool, the OMDS can contribute to this strategy and be of even better service to the maritime sector.

Maarten is actively involved in the NMT's shipbuilding commission - Scheepsbouw Commission 4.0 - where the subject of process innovation is currently being dealt with. Digitalisation will be looked at later this year. He emphasises that BIM is being increasingly required by government clients. 'This creates a cultural shift in the building and maritime industry, where more and more people are thinking and organising in 3D.'

André stresses the importance of efficiency in the exchange of data and the use of uniform objects libraries. He sees it as a challenge for ERIKS, to learn how to receive and deliver independent models, in accordance with the Uniform Objects Library. Maarten adds that demonstrating cost and process advantages through efficiency is important and that setting preconditions, such as working according to the OMDS and 2BA standards, can speed up the process.

André suggests sharing the lessons learned in the installation sector with the maritime world, to reach a proof of concept that will benefit both sectors.